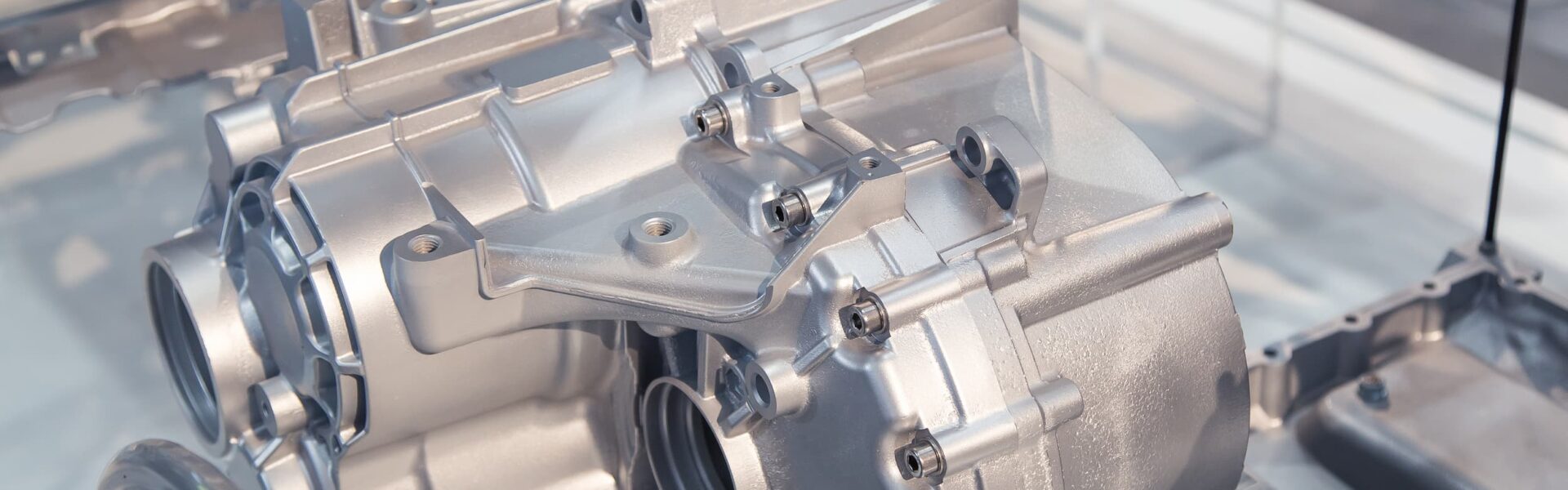

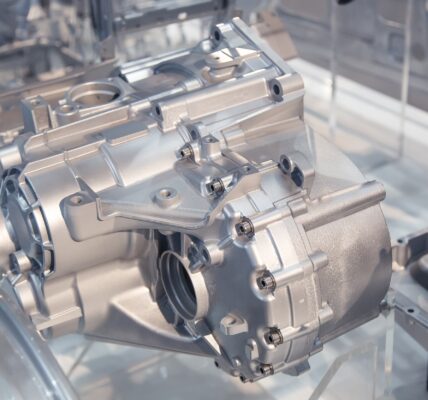

Diecasting has been a key aspect of Malaysia’s manufacturing landscape and is propelling Malaysia ahead as a major actor in the manufacturing. It involves the injection of the molten metal in a mold to create high-precision products utilized in various sectors that include electronics, automotive and other consumer goods. Malaysia’s growth in the diecasting business is driven by strategically-planned government policies as well as technological advances as well as a highly skilled workforce which all contribute to Malaysia’s prosperity and reputation as a place to be for premium manufacturing.

The Malaysian government is a key player in encouraging the development of the diecasting business. Through initiatives such as that of the Malaysian Investment Development Authority (MIDA) as well as the Economic Transformation Programme, the government has encouraged significant international investments as well as facilitated the acceptance of the latest techniques. Strategies aimed at diversification of industries and modernization have helped create an environment that allows diecasting businesses to prosper. In addition, the creation of special industrial zones with the latest technology has given the required support to manufacturing companies from both the local and global market. The strategic initiatives have helped position Malaysia as an attractive place for precision manufacturing which has significantly increased its manufacturing capability.

Innovation in technology is at the center of Malaysia’s diecasting industry. Utilizing cutting-edge technology including computer-aided designs (CAD) and computer-aided manufacturing (CAM) as well as automation has transformed the process of production. This has enabled the development of intricate highly precise and accurate parts with improved efficiency as well as lower errors. Robotics and automation simplify production, improve efficiency, and reduce the risk of human errors, resulting in better quality products. Monitoring systems that are real-time and continuously updated as well as analytics of data further enhance manufacturing processes and provide valuable insight into the performance of production and helping to identify areas of improvement. Continued investing into research and development assures that Malaysian diecasting is on the cutting edge in technological advancement, ensuring its position as a leader in the world market.

Sustainability is becoming increasingly an important aspect of the industry of diecasting in Malaysia. With the demand worldwide for eco green manufacturing techniques grows, Malaysian diecasters are integrating sustainability practices into their production. They are using recycled material, using energy-efficient technology in addition to implementing waste-reduction strategies. The compliance with internationally-recognized environmental standards and certificates demonstrates the industry’s determination to be sustainable. With a focus on sustainable manufacturing methods and implementing green manufacturing practices, the Malaysian diecasting industry not just is in line with global standards for environmental sustainability, and is also positioned as an ethical and innovative company in the international marketplace. This contributes to an overall goal to reduce the impact on the environment of industrial processes. For more information please visit here Senadiecasting

The growth of human capital is essential to Malaysia’s successful diecasting business. An educated and skilled workforce is vital to maintaining the highest standards in quality as well as driving the development of new technologies. The educational institutions as well as vocational training centres located in Malaysia collaborate with the industry of diecasting to provide specialized training courses which equip employees with essential technical abilities. Regular professional development efforts make sure that workers are up-to-date with new developments regarding diecasting techniques and processes. A focus on education and training creates an atmosphere of excellence as well as technological innovation that allows the company to keep pace with changing requirements of the market and changes in technology. This focus on human capital development can be seen as a testimony to the company’s commitment to sustaining expansion through highly skilled employees.

Diecasting in Malaysia is undergoing a significant change due to strategic government assistance, advancements in technology sustainable initiatives, as well as an educated workforce. All of these factors have helped position Malaysia as a major participant in the worldwide diecasting industry, contributing to diverse high-tech industries as well as boosting Malaysia’s economy. Since Malaysia remains committed to embracing the latest technologies and environmentally sustainable practices and practices, the industry of diecasting will continue to grow and achievement. The evolution of the strategic sector demonstrates Malaysia’s capability to change and adapt and ensure its position on the cutting edge of manufacturing precision on the international arena. With a constant collaboration and dedication to quality The Malaysian diecasting business will definitely remain thriving, driving technological advancement and economic growth throughout the next few years.