Die casting is now an integral manufacturing method in Malaysia which is a major contributor to Malaysia’s economic growth. This process involves the forming of molten metal in a mold using high pressure to make intricate and precise parts, has transformed the way that industry produces parts that are used in various uses. Because it can produce robust and high-quality components swiftly and easily it has been an increasingly popular method for industries including electronics, automotive as well as aerospace. In Malaysia the process has been incorporated into the production process, helping local companies meet the local and international demands for top-quality metal components. With the advancement of technology Die casting continues to be important to Malaysia’s efforts in staying at the forefront of global market for manufacturing.

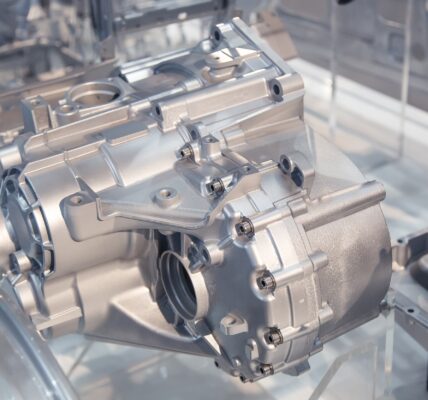

One of the primary benefits that die casting has in Malaysia is its capacity to make parts with incredible accuracy and precision. Die casting allows for the production of components with precise tolerances, complicated geometries as well as smooth finish and are essential in the industries that place performance and high-quality crucial. It is crucial for the automotive industry in which die-cast parts can be found in transmission housings, as well as structural components. Because it allows manufacturers to attain the highest levels of detail and accuracy, die-casting is now an accepted technique for making parts that need to be in line with strict specifications. Die casting does not just improve the overall quality of the product, but also eliminates the requirement for further machining. This can help cut down on time and cost.

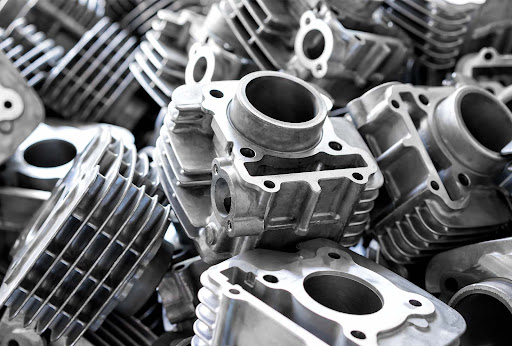

Another factor driving the increasing use for die casting Malaysia is the versatility of materials that it provides. It can be employed to create a variety of different metals such as magnesium, aluminum, zinc as well as copper alloys with distinct properties appropriate for various applications. Die casting of aluminum for example, is frequently used in the automobile manufacturing industry because of its durability and lightweight characteristics. Zinc die casting in contrast is frequently used in manufacturing smaller, complicated parts, particularly for the electronic and consumer industries. The flexibility of the process allows companies in Malaysia to customize their products in accordance with the needs of their particular industry. They can provide specific solutions that maximize efficiency and costs.

The speed and effectiveness of the process makes it a popular choice for Malaysian producers, especially in areas where production of large quantities is required. Its ability to create massive quantities of components within a short period of time make die casting an excellent choice to mass-production. After the mold has been created and used, it is able to be utilized in a series of times to make hundreds of similar components, which reduces lead times and increasing production. This can be particularly advantageous for industries like automobile manufacturing, where parts require large quantities to fulfill global demands for production. In addition, die casting needs less post-production processes like finishing or machining, which makes it more cost-effective. The manufacturing sector in Malaysia is growing in speed, the effectiveness and speed of die casting will ensure firms remain competitive both on the international and local size. For more information please Learn More Here

While it offers many benefits Die casting is a process that has many benefits, but Malaysia has its own challenges in terms of the environment and sustainable management of resources. Die casting involves the use of molten metals. This produces emissions, waste along with other waste products that could cause environmental negative impact. This is why there’s a growing demand for manufacturers to implement more environmentally-friendly practices and lessen the carbon footprint that they create through their activities. Numerous die casting firms located in Malaysia respond to the challenge of implementing efficient energy sources, recycling of metal scrap and using eco green products. With a focus in the direction of sustainability, firms reduce their impact on the environment, but improving their sustainability within an ever-green market.

Die casting is now a crucial element of Malaysia’s manufacturing which has driven innovation and effectiveness in a variety of key industries. Die casting’s accuracy, precision, flexibility, and effectiveness has made it essential for sectors like aerospace, automotive, and electronic components. Since Malaysia is focusing on maintaining its high standards of production and quality, die casting is an important tool to satisfy the needs of markets around the world. Continuous investment in green practices and the latest technology ensures that die casting within Malaysia remains efficient, sustainable, and capable of meeting the ever-changing needs of domestic and international industry. Because of its capacity to create top-quality and cost-effective components quickly and precisely and efficiently, die casting will continue to play an important influence on what the manufacturing future holds for Malaysia.